未分类

Embedded display

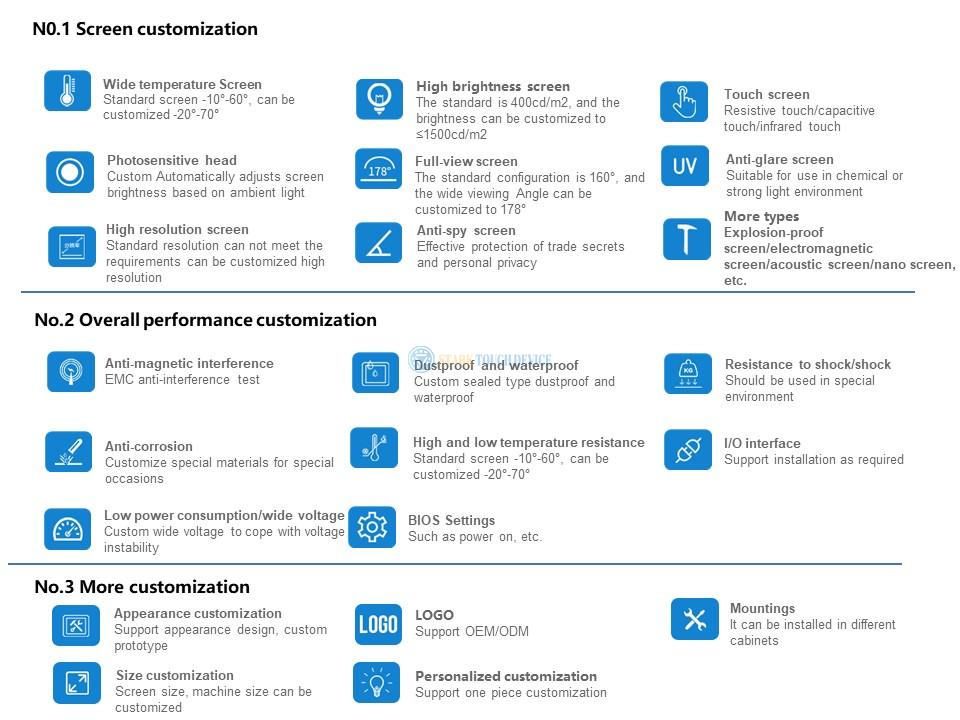

The range of customizable display products includes:

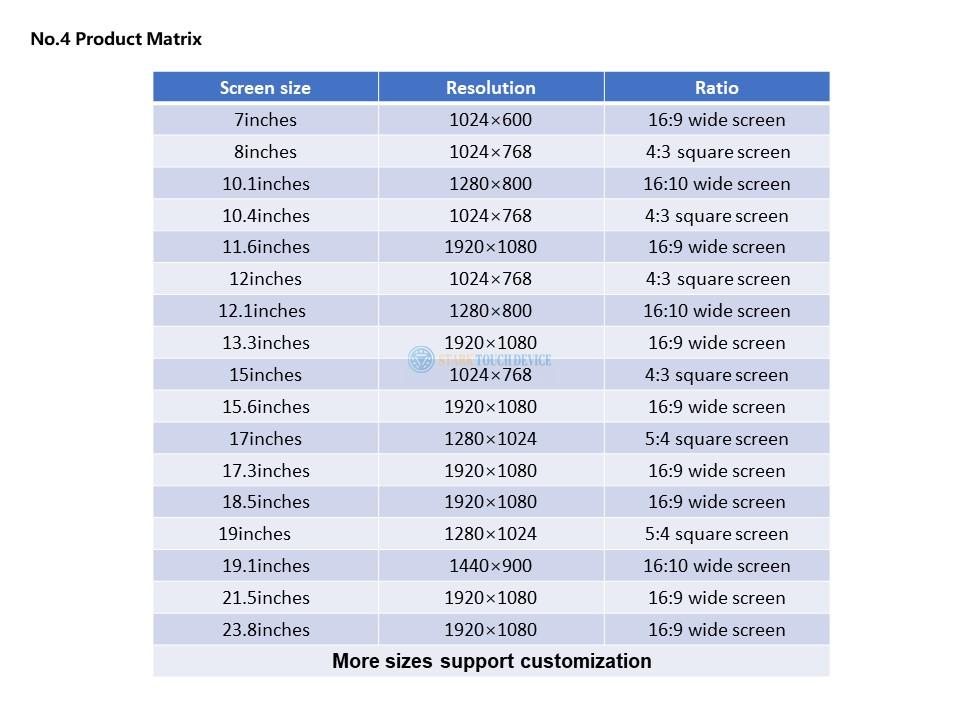

Size: Different sizes of screens can be customized, such as 13.3 inches, 15.6 inches, 21.5 inches, 23.8 inches, 32 inches, etc. 1.

Panel type: Customized VA panel, IPS panel, etc. 1.

Best resolution: You can customize the screen with different resolutions, such as 1920×1080, 2560×1440, 2560×1600, etc. 1.

Backlight type: You can customize LED backlight, CCFL backlight, etc.

Appearance color: You can customize the appearance of different colors, such as black, white, silver, etc.