How Airbags Are Revolutionizing Training Safety for Snowboarders and Skiers

Snowboarding and skiing are thrilling sports that push athletes to their limits, but with that excitement comes the risk of injury. Over the years, ensuring the safety of athletes during training has been a major focus, especially as they attempt increasingly complex tricks and techniques. Airbag technology has emerged as a game-changer in the world of winter sports.

These innovative safety tools are helping athletes train more confidently, minimize injuries, and master their skills with less fear of falling. Let’s explore how airbags are revolutionizing training safety for snowboarders and skiers, making these high-adrenaline sports safer than ever before.

How Do Airbags Work For Skiers And Snowboarders?

Airbags have become an essential tool in the training toolkit for skiers and snowboarders, providing a safety net for athletes as they push the boundaries of their sport. But how exactly do these systems work? Understanding the technology behind airbags and how they help protect athletes can shed light on why they are such a game-changing innovation.

The Technology Behind Airbags

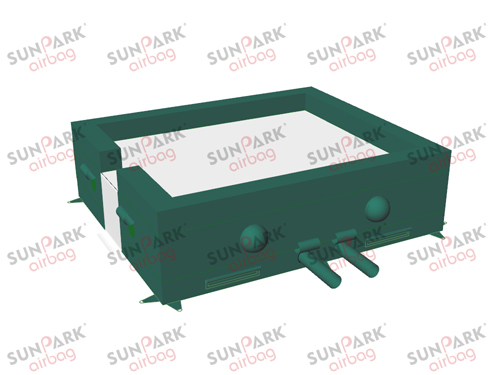

Airbags for skiing and snowboarding training are designed to absorb impact during falls, significantly reducing injury risk. These large inflatable cushions are strategically placed in training areas, enabling athletes to practice tricks and high jumps with a soft landing. They can be adjusted for various heights and angles to meet specific training needs.

The technology behind these airbags combines high-strength materials with rapid inflation systems. Made from durable fabrics that withstand high-impact landings, they feature sensors and valves for quick inflation. Some systems also include automatic inflation technology to optimize air pressure for different training scenarios.

How Airbags Cushion Falls for Skiers and Snowboarders

When a skier or snowboarder loses balance or falls during a trick, the airbag acts as a cushion to absorb the force of impact. Unlike traditional crash mats or snow landings, airbags are designed to distribute the force evenly across the surface, reducing the shock experienced by the athlete. This cushioning effect helps protect joints, muscles, and bones, making it a vital tool for both beginners and professionals looking to refine their skills without the constant fear of serious injury.

How Airbags Work During a Fall

Airbags have revolutionized safety in snow sports, providing a cushioned landing that helps athletes master tricks while minimizing the risk of injury. Here’s a breakdown of features which help these advanced systems function effectively during falls.

Two Chambers System

Dual Chambers

The airbag features a two-chamber design with multi-layered air pockets. The upper chamber is soft for landing, while the lower chamber is firm for stability, creating a realistic landing angle for effective training.

Air Vents System

Adjustable air vents allow for independent control of softness in both chambers, enabling athletes to customize the airbag’s firmness based on personal preferences and training goals.

Anchoring System

Durable stainless steel anchor rings are installed every two meters to secure the airbag to both snow and dirt surfaces, ensuring stability during use.

Removable & Replaceable Top Sheet

The airbag includes a flexible and durable top sheet that can be easily removed and replaced if it wears out, maintaining performance over time.

The Science of Airbag Protection in Skiing and Snowboarding

The science behind airbag technology is based on reducing the amount of force transferred to an athlete during a fall. When someone lands on an airbag, the inflated cushion compresses, increasing the time it takes for the body to come to a stop.

This longer stopping time means less force is exerted on the body, which helps prevent injuries. By using air pressure and volume control, airbags ensure that landings are smooth, making them an effective solution for protecting athletes during high-risk training scenarios.

Types Of Airbags Used in Snowboarding And Skiing

Airbags used in snowboarding and skiing training come in various forms, each designed to meet specific needs and training scenarios. Whether it’s learning basic tricks or pushing the boundaries with advanced maneuvers, different types of airbags help athletes train more safely and confidently. Here’s a look at the most commonly used airbags in snowboarding and skiing.

Ski Jump Airbag

The ski jump airbag is engineered for optimal safety during jumps, incorporating a unique two-chamber impact absorption system consisting of a Catching Zone and a Safety Zone. This design helps athletes land safely while reducing the risk of injury.

- 2-chamber impact absorption system (Catching Zone & Safety Zone) for enhanced safety

- Safety perimeter to ensure secure landings

- Anchoring system for stable fixation in various terrains

- Removable and replaceable top sheet and exit sheet for easy maintenance

- Custom logo branding options with printed designs

- Strong reinforcements made in key areas to withstand impact

- 2-year warranty for reliable performance

Freestyle Skiing Airbag

Freestyle skiing airbags are perfect for athletes looking to hone their skills on complex tricks and jumps. With a robust two-chamber design, these airbags offer an effective cushioning system that provides peace of mind while training.

- 2-chamber impact absorption system (Catching Zone & Safety Zone) to minimize fall impact

- Safety perimeter to facilitate secure landings

- Anchoring system to keep the airbag in place during use

- Removable and replaceable top sheet and exit sheet for straightforward upkeep

- Logo branding options available through printing for personalization

- Reinforced key areas to enhance durability where needed most

- 2-year warranty for assured reliability

Airbag Jump Snowboard

The airbag jump snowboard is tailored specifically for snowboarders looking to practice high-impact tricks safely. With its innovative design, this airbag ensures maximum safety and effectiveness during training sessions.

- 2-chamber impact absorption system (Catching Zone & Safety Zone) for effective impact control

- Safety perimeter designed to ensure secure landings

- Anchoring system to provide stability on various surfaces

- Removable and replaceable top sheet and exit sheet for easy management

- Custom logo branding options available through direct printing

- Reinforced areas for strength and durability where it matters

- 2-year warranty for dependable use

Custom Airbag

Custom airbags are specialized safety solutions crafted to suit specific needs, whether for action sports training, stunts, or entertainment.

- Customizable size, shape, and color to fit any training requirement

- Durable and high-quality materials for long-lasting performance

- Advanced safety features to enhance athlete protection

- Optional branding and logos for personalization and team visibility

Key Benefits Of Airbags in Winter Sports Training

Airbags have transformed the training landscape for winter sports athletes by providing a safer and more effective environment to practice skills and techniques. Here are some key benefits of using airbags in skiing and snowboarding training:

- Enhanced Safety: Airbags significantly reduce the risk of injury during falls. Their cushioned surfaces absorb impact, allowing athletes to focus on improving their skills without the fear of serious harm.

- Improved Confidence: Knowing that a safe landing is guaranteed boosts athletes’ confidence. This encourages them to try more advanced tricks and techniques, leading to faster skill development.

- Versatile Training Tool: Airbags can be used for various activities, from practicing jumps and flips to refining landings. Their adaptability makes them valuable for athletes at all skill levels.

- Realistic Training Conditions: Airbags simulate actual landing scenarios, allowing athletes to experience the dynamics of their maneuvers in a controlled environment. This helps them better prepare for real-world situations on the slopes.

- Customizable Designs: Many airbags come in customizable shapes, sizes, and colors, allowing training facilities to tailor their equipment to specific needs and aesthetics.

- Easy Setup and Maintenance: Airbags are typically easy to inflate, deflate, and transport. Many models also feature removable and replaceable parts, simplifying maintenance and upkeep.

- Long-term Cost Efficiency: Investing in airbags can be cost-effective over time. Their durability and low maintenance requirements make them a smart choice for training facilities looking to enhance athlete safety without frequent replacements.

Wrap-Up!

Airbags are revolutionizing training safety for skiers and snowboarders by providing essential cushioning and support during practice sessions. With their advanced design features and numerous benefits, these airbags not only enhance athlete safety but also foster confidence and skill development. As more athletes and training facilities recognize the value of incorporating airbags, the future of winter sports training looks brighter and safer than ever. Embracing this technology allows athletes to push their limits while minimizing the risks associated with their sport.

With over 10 years of experience, we provide freestyle airbags for ski resorts, theme park, sports and gymnastics facility around the globe. SunparkAirbag? is the leading manufacturer of Airbags for Extreme Sports and Leisure Industries in China.

As extreme sports developed, more and more snowboarders and serious sports enthusiasts are looking for safer training possibilities to progress without risks of getting injured. We create the products for World Champion Snowboarder, famous riders and trampoline parks worldwide. We are deeply committed to the development and improving of our own products.Of ficial website Address:https://www.sunparkairbag.com/